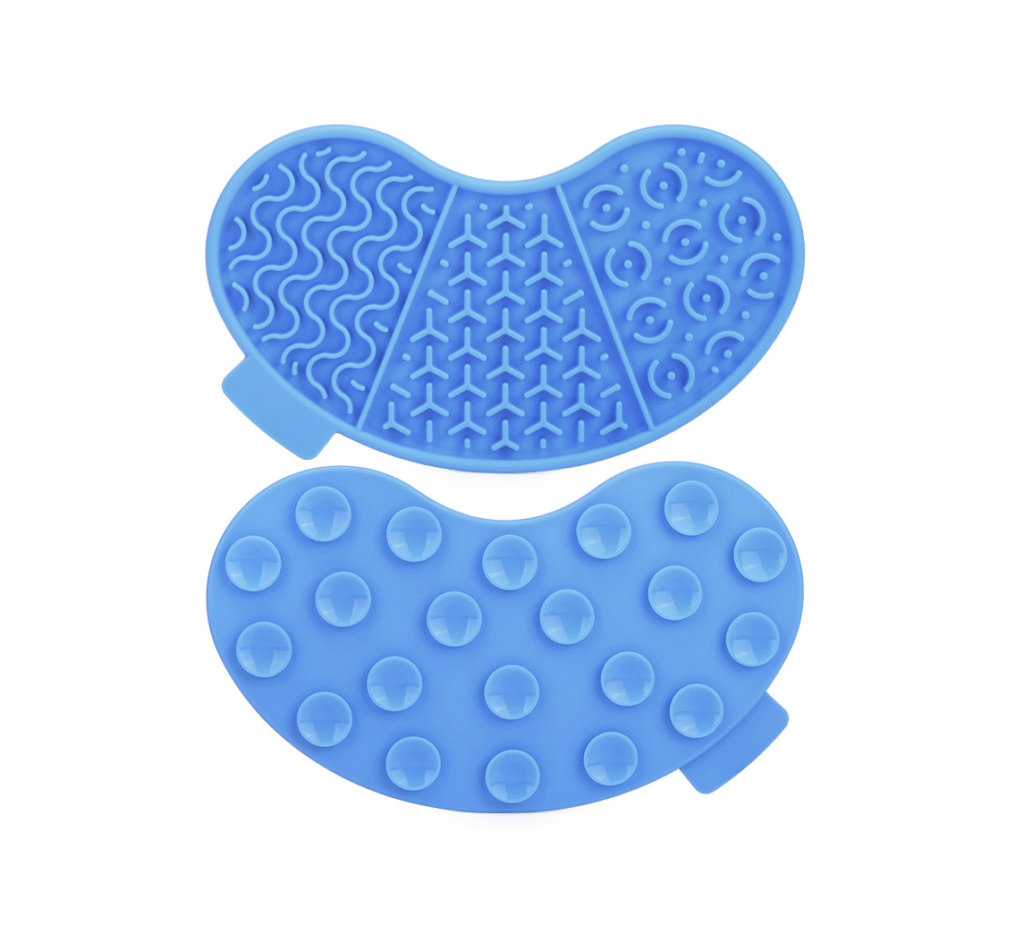

For B2B buyers sourcing custom silicone products—whether kitchenware, pet accessories, or infant care items—understanding mold manufacturing complexities is critical. As an OEM/ODM specialist serving global distributors and brands, we decode the technical challenges and stringent controls ensuring mold reliability.

Why Silicone Molds Demand Precision Engineering

Unlike rigid plastic tooling, liquid silicone rubber (LSR) molds require accounting for material viscosity, thermal expansion, and micro-detail replication. Even minor deviations cause:

- Part Defects: Flash, air traps, dimensional inaccuracies

- Tooling Failures: Premature wear, cavity damage

- Costly Delays: Production halts, rework cycles

Top 4 Manufacturing Challenges & Our Control Solutions

1. Material Selection & Shrinkage Control

Challenge:LSR shrinks 2-4% during curing, risking dimensional drift.

Our Controls:

- Finite Element Analysis (FEA) simulation of shrinkage patterns

- Material-specific mold compensation algorithms

- Batch testing of silicone rubber consistency

2. Complex Parting Line Integrity

Challenge:Complex geometries create vulnerable seam points prone to flash.

Our Controls:

- 5-axis CNC machining of mold cores/cavities (±0.02mm tolerance)

- Automated optical scanning for micron-level seam verification

- Pressure sensors in production runs to detect early wear

3. Venting & Air Trap Elimination

Challenge:Trapped air causes voids and incomplete fills in dense textures.

Our Solutions:

- Micro-venting channels (<0.005″) integrated into CAD designs

- Vacuum-assisted injection systems for high-detail molds

- X-ray inspection of first-article samples

4. Durability for High-Volume Runs

Challenge:Abrasive LSR compounds degrade mold surfaces over time.

Our Protections:

- Hardened tool steel (HRC 48-52) for cavitie

- PVD/PECVD surface coatings (e.g., TiAlN) reducing friction

- Preventive maintenance logs tracking injection cycles

Advanced Process Control in Our Facility

To ensure mold-to-mold consistency for global clients, we deploy:

- Digital Twin Monitoring: Real-time injection pressure/temp data vs. simulated ideal

- Statistical Process Control (SPC): Tracking critical variables (cure time, demolding force)

- Moldflow® Analysis: Pre-production validation of gate placement and flow fronts

Your Competitive Edge: Precision-Optimized Silicone Tooling

For importers and distributors, robust mold engineering directly impacts:

✅ Product quality consistency across batches

✅ Faster cycle times for high-volume orders

✅ Lower per-unit costs through tool longevity

Partner with Precision

Demand more than generic silicone molds. As your ODM/OEM specialist, we merge tooling expertise with material science to solve complex product requirements—from heat-resistant kitchen tools to FDA-compliant baby products.

Ready to optimize your silicone product manufacturing?

[Request a Technical Consultation] (Link to our contact page)